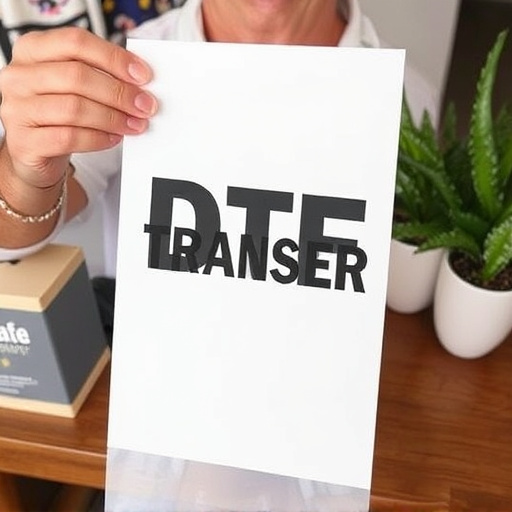

Direct-to-Film (DTF) transfer is a modern print creation method, offering swift and versatile alternatives to traditional screen printing. It directly prints intricate designs onto special film using high-res printers, eliminating screens, and applying the design to surfaces like fabric for vibrant, detailed DTF prints with fine lines. DTF's speed, efficiency, and consistency make it ideal for small batches, on-demand printing, and diverse materials, ensuring professional results. While traditional screen printing is a classic method for high-quality DTF prints with intricate details and excellent color accuracy, DTF printing revolutionizes customization with faster turnaround times, eliminating setup processes. Both methods have distinct strengths: screen printing for bulk production runs and fine details, DTF for small batches, personalized items, and versatile materials. Financial considerations include lower upfront costs for DTF but higher per-unit ink cartridge and film expenses compared to traditional screen printing's one-time tool purchases.

In the realm of printing, Direct-to-Film (DTF) transfer has emerged as a game-changer, challenging the traditional screen printing method. This article delves into the contrasting approaches of DTF and screen printing, offering insights for businesses and designers. Understanding DTF’s digital nature provides a modern solution with faster turnaround times. While screen printing remains iconic, DTF prints excel in quality and speed. We explore cost implications, ideal applications, and how these methods shape various industries, empowering informed choices between these innovative printing techniques.

- Understanding Direct-to-Film (DTF) Transfer: A Modern Printing Approach

- Traditional Screen Printing: The Classic Method

- DTF's Advantage: Faster Turnaround Times

- Screen Printing vs DTF in Terms of Quality and Detail

- Cost Analysis: DTF vs Traditional Screen Printing

- Applications and Use Cases for Each Printing Technique

Understanding Direct-to-Film (DTF) Transfer: A Modern Printing Approach

Direct-to-Film (DTF) transfer is a cutting-edge printing method that has revolutionized the way we create and produce custom prints, particularly in the apparel industry. Unlike traditional screen printing, which involves setting up intricate screens for each design, DTF offers a more efficient and versatile approach. In this modern technique, designs are directly printed onto a special film using high-resolution printers, eliminating the need for screens. This film is then carefully applied to various surfaces, such as fabric, allowing for precise and detailed prints.

DTF Printing has gained immense popularity due to its ability to produce high-quality, vibrant DTF Prints with intricate details and fine lines. The process is swift and efficient, making it an attractive option for small batch productions and on-demand printing. Moreover, this technology enables printers to achieve consistent results across different materials and substrates, ensuring a professional finish every time.

Traditional Screen Printing: The Classic Method

Traditional screen printing is a classic method that has been around for decades, offering high-quality prints on a variety of materials. This process involves creating a stencil on a fine mesh or fine fabric, which allows ink to pass through in specific areas while blocking it in others. The design is then transferred onto the desired substrate, whether it’s t-shirts, posters, or even ceramics, through direct application of ink onto the screen. Each color in the design requires a separate screen, and the process involves multiple steps, including setting up the screens, printing the inks, and curing them with heat. Despite being a more labor-intensive and time-consuming technique compared to digital methods, traditional screen printing remains popular for its ability to produce vibrant, long-lasting DTF prints with excellent color accuracy.

This classic method is particularly favored for creating custom designs in small to medium batches, ensuring each print has a unique, hand-crafted feel. The versatility of DTF transfer allows for intricate details and fine lines, making it suitable for both simple logos and complex artwork. Screen printers can experiment with various ink types, finishes, and effects, resulting in rich, deep colors and diverse textures. The process also lends itself well to collaborative projects, as artists and designers can work together to create unique, limited-edition pieces, ensuring a truly special end product.

DTF's Advantage: Faster Turnaround Times

Direct-to-film (DTF) printing offers a significant advantage over traditional screen printing methods when it comes to turnaround times. With DTF, designs are transferred directly onto the substrate using advanced digital printing technology, eliminating the need for intricate setup and screen preparation. This streamlines the process, allowing for quicker production of custom prints. Whether you’re looking to create personalized T-shirts, promotional materials, or small batch runs, DTF transfers provide an efficient solution.

Compared to screen printing, where each color requires a separate screen and meticulous hand work, DTF printing can produce complex designs in record time. This efficiency is particularly beneficial for businesses or individuals needing fast turnaround without compromising on quality. DTF prints offer vibrant colors, sharp details, and a wide range of applicable materials, making it a versatile choice for various projects.

Screen Printing vs DTF in Terms of Quality and Detail

When comparing screen printing to direct-to-film (DTF) transfer methods, the quality and detail of the final prints differ significantly. Screen printing, a traditional technique, excels in delivering intricate details and vibrant colors due to its precise control over ink deposition. Each color requires a separate screening process, allowing for fine lines and subtle nuances to be captured on various materials. This method is particularly favored for high-quality, long-lasting prints on textiles and other surfaces.

In contrast, DTF printing offers a more efficient approach with superior resolution. By using digital files to transfer images directly onto the substrate, DTF ensures consistent and sharp details across all colors in a single pass. This makes DTF ideal for producing high-quality prints on demand, as it reduces setup time and is suitable for both small and large-scale productions. DTF transfers also provide an advantage in terms of versatility, accommodating various materials without the need for specialized screens.

Cost Analysis: DTF vs Traditional Screen Printing

Direct-to-film (DTF) transfer and traditional screen printing are distinct methods with varying cost implications. In terms of upfront costs, setting up a DTF system can be more economical as it requires fewer specialized tools and equipment compared to screen printing presses. This accessibility makes DTF an attractive option for small businesses or individuals looking to enter the custom printing market without significant investment.

However, the ongoing expenses differ significantly. Screen printing involves purchasing screens, emulsion, and frames, which can accumulate costs over time as these materials need periodic replacement. In contrast, DTF primarily relies on ink cartridges and films, which may have higher per-unit prices but offer more flexibility in terms of design changes and smaller minimum order quantities. For businesses with consistent demand for custom prints, the recurring costs of consumables should be carefully considered when choosing between DTF transfer and traditional screen printing methods.

Applications and Use Cases for Each Printing Technique

Direct-to-film (DTF) transfer and traditional screen printing are two distinct methods with unique applications across various industries. DTF is a modern technique that has gained popularity for its versatility and efficiency, especially in the production of custom apparel and promotional items. This process involves transferring ink directly onto fabric or other materials using heat and pressure, enabling intricate designs and a wide range of print types, from simple text to complex graphics. DTF prints are known for their vibrant colors, fast drying times, and ability to create soft, comfortable fabrics.

Traditional screen printing, on the other hand, is a time-honored method that remains indispensable in many sectors. It is commonly used for bulk production runs, offering exceptional durability and precision for designs with fine details. Screen printing is ideal for creating custom t-shirts, posters, signs, and even industrial markings. This technique allows for an array of print colors and inks, catering to diverse brand identities and artistic expressions. While it may not be as swift or cost-effective as DTF for small-batch production, screen printing remains a reliable choice for high-volume printing requirements.